Advanced Mining offers the world's widest range of equipment for rock drilling, rock excavation, processing, demolition, bulk-materials handling and equipment for surface and underground mining.

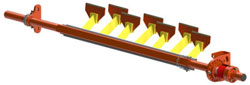

Secondary belt cleaners

Secondary cleaners are designed to be installed immediately after the head pulley to remove fine carryback adhering to the belt. Secondary belt cleaners are generally set up behind the tangent point where the belt leaves the pulley and are responsible for final belt cleaning.

Models

Secondary belt cleaner HB210

(former name MU30)

Secondary belt cleaner HB210

(former name MU30)

HB210 secondary belt cleaner is suitable for mobile conveyor applications but also for any other application where the space below pulley is limited.

Features and values

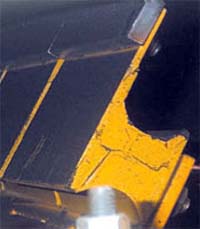

- Blade material; Tungsten carbide

- Spring steel structure keeps the material from adhering to the belt cleaner and reduces maintaining

Key specifications HB110

| Belt width | 400-1400 mm |

| Recommended belt speed | 0.5-2.8 m/s |

Secondary belt cleaner HB220 (former name MAX6)

HB220 is a secondary cleaner with flexible blade arms that enable usage even with worn belt surfaces and sticky material. It also allows variances in belt thickness.

HB220 is a secondary cleaner with flexible blade arms that enable usage even with worn belt surfaces and sticky material. It also allows variances in belt thickness.

Features and values

- Blade materials: Tungsten carbide, stainless steel or acid proof steel

- Tensioning handled by special torsion spring tensioning device

Key specifications HB120

| Belt width | 400-2000 mm |

| Recommended belt speed | 0.5-3.5 m/s |

Secondary belt cleaner HB230 (former name Pit-Trojan)

HB230 is a secondary cleaner for fines equipped with tungsten carbide tips. Tips are developed for very abrasive materials and for demanding process industry.

HB230 is a secondary cleaner for fines equipped with tungsten carbide tips. Tips are developed for very abrasive materials and for demanding process industry.

Features and values

- Adjusting of the blade pressure together with flexible rubber cushion secure the right blade position against the belt

- Linear touch enables small blade pressure, which saves the belt and gives a good cleaning result

Key specifications HB130

| Belt width | 400-2000 mm |

| Recommended belt speed | 1.5-3.5 m/s |

Secondary belt cleaner HB235 (former name Pit-Trojan Heavy-Duty)

HB235 is a secondary cleaner for fines designed for heavy-duty applications. and equipped with tungsten carbide blades.

HB235 is a secondary cleaner for fines designed for heavy-duty applications. and equipped with tungsten carbide blades.

Features and values

- Operating area is of very abrasive materials

- Adjusting of the blade pressure together with flexible rubber cushion secure the right blade position against the belt

- Linear touch enables small blade pressure, which saves the belt

Key specifications HB135

| Belt width | 1200-2400 mm |

| Recommended belt speed | 2.5-3.8 m/s |

Secondary belt cleaner HB250 (former name MAX7)

HB250 secondary belt cleaner is mainly designed for reversible conveyors but can be used also in one direction conveyors heavy-duty applications and equipped with tungsten carbide blades.

HB250 secondary belt cleaner is mainly designed for reversible conveyors but can be used also in one direction conveyors heavy-duty applications and equipped with tungsten carbide blades.

Features and values

- Operating with reversible conveyors

- Linear touch enables small blade pressure, which saves the belt

Key specifications HB140

| Belt width | 400-1600 mm |

| Recommended belt speed | 1.0-3.0 m/s |

Pit Trojan (Stainless Steel) AUS

Supplied with Tungsten tips (polyurethane as an option). Designed for fine cleaning of the conveyor and generally removes product less than 0.5mm. Available in a model to suit reversing conveyors and it can be fitted with an optional spraybar.

Supplied with Tungsten tips (polyurethane as an option). Designed for fine cleaning of the conveyor and generally removes product less than 0.5mm. Available in a model to suit reversing conveyors and it can be fitted with an optional spraybar.

Features and values

- Utilises Sandvik Tungsten with 59% longer life than comparable brands.

- Each tip is connected to a separate rubber cushion for accurate tip tension.

- Self adjusting.

Key specifications HB150

| Belt width | 300–2500 mm |