Advanced Mining offers the world's widest range of equipment for rock drilling, rock excavation, processing, demolition, bulk-materials handling and equipment for surface and underground mining.

Tertiary cleaners

Tertiary cleaner removes spillage from the belt still there after earlier cleaners. These cleaners clean the belt with less mechanical contact ie less wearing of the belt.

Models

Tertiary cleaner HB270

(former name AIRMAX 10)

Tertiary cleaner HB270

(former name AIRMAX 10)

Effective cleaner for sticky and difficult materials and ripped belts. Thanks to the long and narrow air passage of the blasting nozzle, blasting power can be precisely concentrated, and e.g. water can be blasted off the belt.

Features and values

- For sticky materials

- For ripped belts

- No wearing parts

- This belt cleaner uses pressurized air for keeping the belt clean

- No mechanical contact with the belt

- Can be connected also to the plant’s compressed air network

Key specifications HB110

| Belt width | 500-2000 mm |

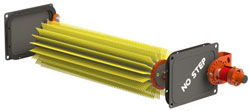

Tertiary cleaner HB280 belt brush

(former name MotoMax)

Tertiary cleaner HB280 belt brush

(former name MotoMax)

HB280 fine cleaner with compact design of pulley motor and brushes makes it the best choice for dry and pulverized materials. Compact construction allows it to be installed even into limited spaces. Wearing material can be chosed according to application from wide selection of materials. Tensioning is taken care automatically and can be monitored at service bridge or with electronical wear indicating system.

Features and values

- Easy to maintain and change the brushes

- Tensioning taken care of by special tensioning device with inductive sensor to monitor the wear and tear of the blades

- Several brush materials available for different applications and conveyed materials

Key specifications HB110

| Belt width | 500-2000 mm |

Tertiary cleaner HB285 belt brush

(former name MotoMax)

Tertiary cleaner HB285 belt brush

(former name MotoMax)

HB285 tertiary cleaner with compact design of pulley motor and brushes makes it the best choice for dry and pulverized materials. Compact construction allows it to be installed even into limited spaces. Wearing material can be chosed according to application from wide selection of materials. Tensioning is taken care automatically and can be monitored at service bridge or with electronical wear indicating system.

Features and values

- Easy to maintain and change the brushes

- Tensioning taken care of by special tensioning device with inductive sensor to monitor the wear and tear of the blades

- Several brush materials available for different applications and conveyed materials

Key specifications HB110

| Belt width | 1600-2200 mm |