Advanced Mining offers the world's widest range of equipment for rock drilling, rock excavation, processing, demolition, bulk-materials handling and equipment for surface and underground mining.

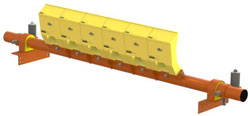

Primary belt cleaners

Primary belt cleaners are generally set up on the head pulley and are responsible for removing the bulk of carry back adhering to the belt. The Sandvik cleaners are easy to install and maintain, and can be equipped with different blade materials.

Models

Primary belt cleaner HB110 (former name BEP31)

Primary belt cleaner HB110 (former name BEP31)

Multiblade cleaner with a very wide operating area. Easy to maintain due to the easy replacing of wearable parts. Wearable parts available in several different materials according to application. Recommended for use in crushing plants and in wood chip conveyors.

Features and values

- HB110 is a multi-blade cleaner for very wide operating area

- Blade materials: Polyurethane, polyurethane blade filled with aluminum oxide granules, polyethylene, polyurethane blade with tungsten carbide tip part

- Easy to maintain

- Reliable spring tensioning

Key specifications HB110

| Belt width | 500-1400 mm |

| Pulley diameter | 320-630 mm |

| Recommended belt speed | 0-3 m/s |

Primary belt cleaner HB120(former name MAX3)

Reliable multiblade cleaner that meets the highest demands related to maintenance and cleaning efficiency. The blades, which can be chosen according to application from wide selection of materials, can be replaced very easily. Tensioning is automatically adjustable and can be monitored at service brigde or with electronical wear indicating system.

Reliable multiblade cleaner that meets the highest demands related to maintenance and cleaning efficiency. The blades, which can be chosen according to application from wide selection of materials, can be replaced very easily. Tensioning is automatically adjustable and can be monitored at service brigde or with electronical wear indicating system.

Features and values

- With flexible blades enabling usage even with worn belt surfaces

- Blade materials: Polyurethane, or polyurethane filled with aluminum oxide granules, polyurethane blade with tungsten carbide tip

- The 2-piece cleaner blade offers the advantage of replacing only the worn out tip of the blade,while the base remains unchanged

- Tensioning handled by special tensioning device

Key specifications HB120

| Belt width | 400-1800 mm |

| Pulley diameter | 320-630 mm |

| Recommended belt speed | 1-3.5 m/s |

Primary belt cleaner HB130 (former name Pit-Boss)

Multiblade cleaners that have proved their efficiency with several kinds of materials. Placement on drive pulley just below material flow. HB130 primary cleaner is equipped with tungsten carbide blades developed for demanding process industry.

Multiblade cleaners that have proved their efficiency with several kinds of materials. Placement on drive pulley just below material flow. HB130 primary cleaner is equipped with tungsten carbide blades developed for demanding process industry.

Features and values

- Equipped with tungsten carbide blades, developed for very abrasive applications and for demanding process industry

- Open construction prevents the cleaner from getting plugged

- Simple torque and blade adjustment system with small blade pressure saves belt

- HB130 primary cleaner is designed for easy maintenance, thanks for the blade cassette structure

Key specifications HB130

| Belt width | 400-1800 mm |

| Pulley diameter | 320-800 mm |

| Recommended belt speed | 1.5-3.6 m/s |

Primary belt cleaner HB135 (former name Pit-Boss Heavy-Duty)

HB135 primary cleaner designed for heavy-duty applications is equipped with tungsten carbide blades. Blades are developed for demanding applications in heavy-duty process industries.

HB135 primary cleaner designed for heavy-duty applications is equipped with tungsten carbide blades. Blades are developed for demanding applications in heavy-duty process industries.

Features and values

- Blade material ensures good wear resistance even with abrasive materials. Open construction prevents the cleaner from getting plugged

- Simple torque and blade adjustment system with small blade pressure saves belt

- Blade cassette structure simplifies maintenance work

Key specifications HB135

| Belt width | 1200-2400 mm |

| Pulley diameter | 630-1200 mm |

| Recommended belt speed | 1.5-4.0 m/s |

Primary belt cleaner HB140 (former name Pit Bull)

HB140 is designed for use as primary in heavu-duty conveyors. Blades are very wear resistant and provide a good cleaning result. HB140 belt cleaners works even when the material includes large lumps.

HB140 is designed for use as primary in heavu-duty conveyors. Blades are very wear resistant and provide a good cleaning result. HB140 belt cleaners works even when the material includes large lumps.

Features and values

- Can be used also with mechanical joints and worn out belt surfaces

- Blade material is polyurethane

- Simple torque system with rubber isolators

Key specifications HB140

| Belt width | 1000-2000 mm |

| Pulley diameter | 630-1000 mm |

| Recommended belt speed | 0-3.5 m/s |

Primary belt cleaner HB150 (former name Pit-Bull Extra Heavy-Duty)

HB150 is a primary cleaner designed for heavy-duty mining applications. The cleaner is supplied with wear resistant polyurethane blades. HB150 belt cleaner works even when the material includes lareg lumps and the belt surface is worn out.

HB150 is a primary cleaner designed for heavy-duty mining applications. The cleaner is supplied with wear resistant polyurethane blades. HB150 belt cleaner works even when the material includes lareg lumps and the belt surface is worn out.

Features and values

- HB150 is a primary cleaner for extreme applications and can be used with mechanical splices. The 2-piece cleaner blade offers the advantage of replacing only the worn out tip of the blade, while the base remains unchanged

- Blade material is polyurethane

- Simple torque system with rubber isolators

Key specifications HB150

| Belt width | 1200–2600 mm |

| Pulley diameter | 1000-1600 mm |

| Recommeded belt speed | 0-3.9 m/s |